How it works

We Tailor Technology to Unlock the Full Potential of Challenging Feedstocks

At MethaPlanet, we transform organic residual streams into renewable energy, with maximum CO₂ reduction as our guiding principle. It starts at the source. We collect straw-based horse manure, our primary feedstock, directly from site and optimise it through tailored pre-treatment before processing it in our advanced biogas plants.

Our technology adapts to complexity. By aligning pre-treatment with the specific needs of different anaerobic digestion systems, we optimise feedstock compatibility, ensuring efficient biomethane production even from the most challenging materials.

The process is fully circular. Biomethane is upgraded on-site, and every by-product is given a second life, from soil enhancers to greenhouse applications. Unlike others who pursue volume, we focus on impact. Through smart logistics, local processing, and strong partnerships, we deliver meaningful and structural emission reductions across the value chain.

For us, waste is not a challenge, it's part of the climate solution. And technology is the key to unlocking its full potential.

Our Process within the Ecosystem

1.

Locally sourced

At MethaPlanet, we specialise in transforming hard-to-digest organic residues, that would otherwise go underutilised. These feedstocks, such as straw-based horse manure, present a challenge for most conventional biogas plants due to their fibrous structure and high lignin content.

This is where our expertise begins. We source straw-based manure directly from horse owners within a 50 kilometer radius of our biogas facility. To reduce emissions at the source and improve feedstock quality, we install dedicated dry storage units at these partner locations. This not only prevents harmful emissions during storage, but also makes the collection process more efficient.

Our local sourcing model strengthens community partnerships, reduces transport emissions, and ensures a stable, high-quality feedstock supply. Looking ahead, we aim to expand our impact by tackling a broader range of overlooked organic residues, creating value from waste and advancing a truly circular bioeconomy.

2.

Locally produced

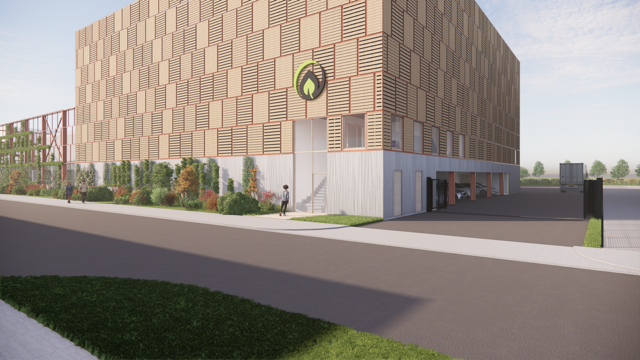

MethaPlanet specialises in the advanced preparation of hard-to-digest organic residues, most notably straw-based horse manure, using strategically located processing facilities. Each facility is carefully positioned to maximise accessibility for local horse owners and leverage robust infrastructure, ensuring efficient collection and minimal transport emissions.

Our modular preparation systems are fully adapted to local conditions, including the type of feedstock and the specific biogas plant configuration. By breaking down the complex lignin structures in these residues, we transform them into high-quality feedstock optimised for biogas production. This significantly improves both the speed and efficiency of the digestion process, solving common industry issues like input shortages and low yields. The biogas produced is upgraded to biomethane on the same site.

A cornerstone of our innovation is the Maxximizer, a patented technology developed by MethaPlanet to convert straw-based horse manure into compact, high-yield energy pellets. This process not only breaks down lignin to improve digestibility, but also triples biogas output in just one third of the time compared to conventional methods. The resulting pellets are easy to store and transport, offering exceptional flexibility for a wide range of biogas operations.

While a large portion of these pellets fuels MethaPlanet’s own plug flow biogas plant, they are also available to third-party operators seeking to boost their plant performance and sustainability.

3.

Locally used

Biomethane

During the anaerobic digestion process, organic residual streams are broken down by microorganisms in an oxygen-free environment. This produces biogas, a mixture of methane and carbon dioxide. At MethaPlanet, we upgrade this raw biogas on site into biomethane by removing the CO₂ and other impurities. The resulting biomethane meets grid quality standards and is injected directly into the national gas network, where it replaces fossil gas and contributes to the Dutch energy transition.

Biogenic CO₂

The CO₂ that is removed during the upgrading of biogas is not released into the atmosphere. Instead, we capture and purify this biogenic CO₂ for reuse. Through our regional pipeline network, the captured CO₂ is delivered to greenhouses, who use it to stimulate plant growth. In this way, we close the loop between residual streams and food production, giving carbon a new and productive role.

Digestate

What remains after digestion is digestate, a nutrient-rich residue that contains organic matter and minerals. Instead of treating it as waste, we return it to local soils as a natural soil improver. Farmers and horse owners use digestate to enrich their land, improve soil structure and reduce the need for synthetic fertilisers. This creates a fully circular system in which every part of the process supports circularity.

Results with impact

50.000

Tonnes of CO₂ emissions saved yearly.

80.000

Tonnes of straw-based manure processed.

9.000.000

Cubic meters of biomethane produced.